Seamless Machinery Commissioning: Powering Your Food Production from Day One

At Navatech, we understand that the successful commissioning of machinery is a crucial step in getting your food production line up and running smoothly. With our expertise in the food industry and deep understanding of the Spanish market, we offer a comprehensive commissioning process that ensures your machinery operates at its full potential right from the start.

What is Commissioning?

Commissioning is the process of ensuring that your newly installed machinery is set up correctly, tested, and fully operational according to the manufacturer’s specifications and your specific production needs. It’s the final step before your equipment goes live, and it’s critical to minimizing downtime, avoiding costly mistakes, and ensuring your production processes run efficiently.

Our Commissioning Process

- Pre-Commissioning PreparationBefore the machinery arrives at your site, Navatech ensures that all necessary preparations are in place. This includes verifying that all components are delivered, inspecting the installation site, and reviewing all technical documentation. We work closely with your team to plan every detail, ensuring a smooth and efficient commissioning process.

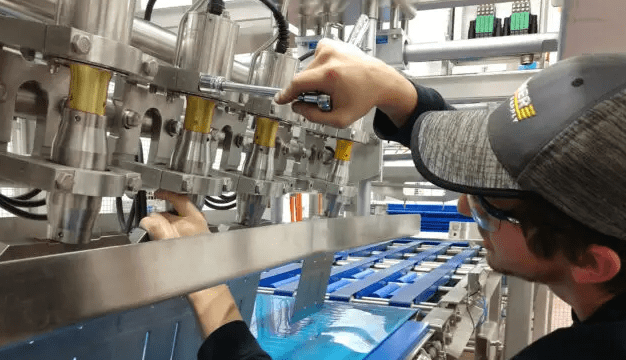

- Installation VerificationOnce your machinery is installed, our team conducts a thorough inspection to verify that everything is correctly set up according to the manufacturer’s guidelines. We check all connections, calibrate settings, and ensure that the installation meets all safety and operational standards. This step is crucial to preventing any issues before the equipment is put into operation.

- Functional TestingWith the installation verified, Navatech performs comprehensive functional tests to ensure that the machinery operates as expected under real production conditions. We simulate actual production scenarios, test all controls and safety features, and fine-tune the equipment to match your specific requirements. This process helps identify and resolve any potential issues before they impact your operations.

- Operator TrainingProperly trained operators are essential for maintaining the efficiency and longevity of your machinery. During the commissioning process, Navatech provides hands-on training for your staff, ensuring they are fully equipped to operate and maintain the equipment. Our training covers everything from basic operation to troubleshooting and maintenance, empowering your team to keep your production line running smoothly.

- Final Handover and DocumentationAfter successful commissioning, Navatech provides a detailed report documenting the entire process, including test results, calibration settings, and any adjustments made. We also supply all necessary documentation, such as user manuals and maintenance guides, to support ongoing operations. Our final handover ensures that your team has everything they need to maintain optimal performance.

Why Choose Navatech for Commissioning?

Navatech is committed to ensuring that your machinery is commissioned correctly and efficiently, minimizing downtime and maximizing productivity. Our deep knowledge of the food industry in Spain, combined with our technical expertise, makes us the ideal partner for your commissioning needs. We take pride in delivering a seamless experience that gets your production line up and running without a hitch.